Hygienic Fabrics & Filters offers custom converting and job shop services. An ISO Class 6-Compliant clean room is available for contaminant-sensitive jobs. Converting services include roll good slitting and rewinding as well as roll good sheeting. Our industrial sewing team uses automated and manual sewing machines to sew your items using your thread color and stitch type. We also offer RF and sonic welding. Job shop services range from flat-bed die cutting to finishing services, including assembly, subassembly, folding, and packaging. We also custom manufacture to your specification. Let us know how we can help you!

Our Sheboygan Location Is ISO 9001:2015 Certified

Our Sheboygan Location Is ISO 9001:2015 Certified

Our Sheboygan Location Is ISO 9001:2015 Certified

Our Sheboygan Location Is ISO 9001:2015 Certified

Services

Custom Contract Industrial Converting Services

Hygienic Fabrics & Filters also offers a clean room option for all of our services to ensure contaminant-free products.

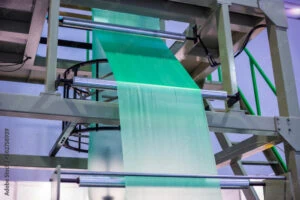

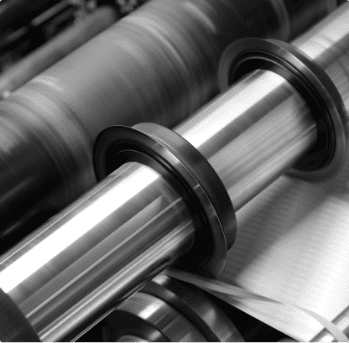

Roll slitters are used to convert large wide rolls to narrower rolls. A roll slitter can convert a 36″-wide roll into two 18-wide rolls or three 12″-wide rolls. We convert roll goods up to 72″ wide.

Industrial Slitting & Rewinding

Custom roll slitting enables you to limit material waste. Custom-width slitting enables you to accurately fit your material into your design without additional fabrication. We can slit your product with straight cut edges or pinked edges. We are able to slit substrates with or without adhesive.

Hygienic Fabrics & Filters’ Sheboygan, Wisconsin, slitting and rewinding department has numerous industrial state-of-the-art high-speed slitting and rewinding machines that enable us to convert material at high speeds and produce quality reworked material with tremendous accuracy. Material can be slit to specific custom widths and lengths onto a range of core diameters. We can unwind, slit, and rewind a variety of materials such netting, woven, nonwoven, plastic, rubber, extruded films, paper, adhesive-backed materials, and more.

Our diversified equipment processes various grades of film, laminates, nonwoven materials, and customer-supplied proprietary materials. Hygienic Fabrics and Filters also provides consignment slitting services for customer-supplied materials that are compatible with our machines

Industrial Sheeting

We are able to work with a wide range of materials including adhesive-coated tapes, films, woven fabrics, nonwovens, netting, silicone, polyethylenes, and polypropylenes. We offer top-quality sheeting services that meet high industry standards. We serve multiple industries such as industrial, chemical, food, aerospace and plastics. Contact Hygienic Fabrics & Filters’ Sheboygan, Wisconsin, office today to learn more about our advanced sheeting capabilities.

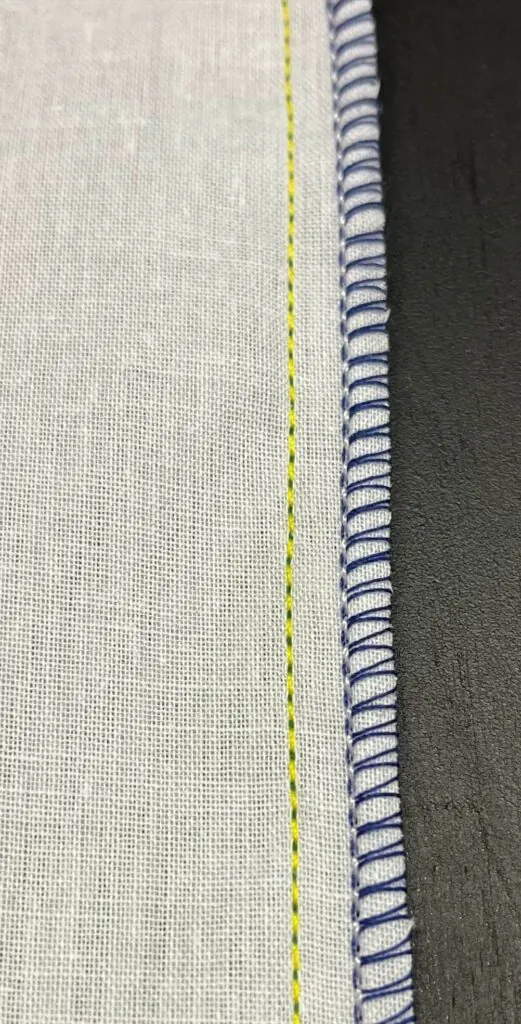

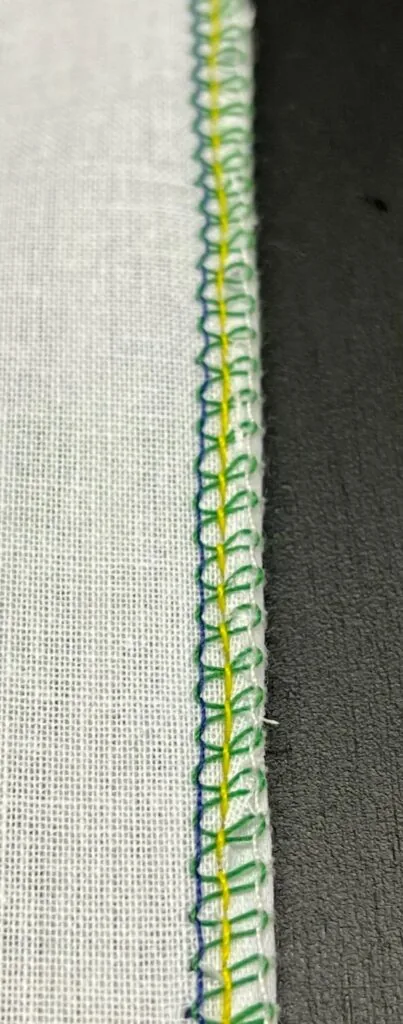

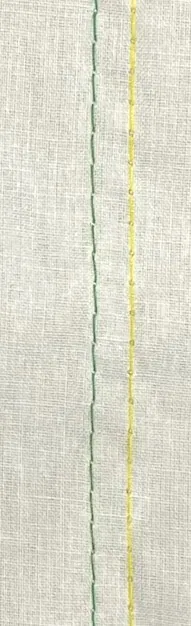

Industrial Sewing

Industrial sewing manufacturers produce products that are designed for repeatable quality on every order. Industrial sewing contractors have the expertise and equipment to work with a wide range of fabrics and materials, including coated vinyl and polyester, leathers, and more. We help source fabric and can recommend alternate fabrics for your product. We can cut many shapes and layers of fabric at once with precise cuts.

Hygienic Fabrics & Filters can assist in the design and construction of commercial sewing options for your products.

Both our Lanark, Illinois, and Sheboygan, Wisconsin, facilities offer complete industrial contract sewing services to meet your needs. We use automated and manual industrial sewing machines. Following is a partial list of our sewing department capabilities:

- Single and Double Needle Stitching

- Chain, Lock, and Overlock (Merrow) Stitching

- Capable of making Extended-Length Bags

- Seam Welding and Seam Taping

- Standard and Custom Bags

- Specialty Cheese Bandages

Following is a partial list of materials with which we have a long history of experience:

- Felts

- Wovens

- Elastic

- Zippers

- Nonwovens

- Membranes

- Ballistic Nylons

- Vinyl

- Plastic

- Mesh

- Velcro

Services include installation of hardware and ancillary items such as:

- Grommets

- Snaps

- Velcro

- Zippers

- Ties

- Draw Cords

- Hooks

- Fasteners

- Achoring rings

Flat-Bed / Industrial Die Cutting

We can drill various hole sizes and make notches in your material, which is great for marking locations of grommets, snaps, or folds. Fabric die cutting allows for virtually any shape to be cut with consistency and accuracy. We can use your existing dies, or our team can create a custom die.

Hygienic Fabrics and Filters offers rapid prototyping and short lead times as well as special packaging for medical products. Our state-of-the-art equipment, cutting-edge technology, and highly qualified and experienced staff distinguish us from the competition.

The steel rule die is the heart of die cutting. Formed metal blades are positioned in a wooden board to form a “cookie cutter,” which enables perfect duplication of your parts within .020″ every time. Complex shapes, stars, circles, and many different patterns are possible with a steel rule die. Using steel rule dies, we can die cut foam, sheet plastic, corrugated plastic, chipboard, fabric, rubber, felt, cork, thin metals, wood, acrylic, composites, fiberglass, magnets, sponge, custom die cuts or any other flat material normally found in the industry.

Hygienic Fabrics & Filters can use customer-supplied steel rule dies or order a steel rule die for the job based on a dimension drawing. The tooling cost to create the die will be separately listed in your quote from Hygienic Fabrics & Filters.

All of the products we cut require a very clean production environment and perfect packed appearance. We take care to follow all instructions for cutting and packaging regardless of job size. Hygienic Fabrics and Filters provides precision die cutting services supporting tight tolerances, small and large part sizes, and various production volumes. Here, at our Made in the USA manufacturing facility in Sheboygan, Wisconsin, we provide precision die cutting services using high-quality tooling and state-of-the-art equipment. Hygienic Fabrics & Filters can die cut materials such as:

- Membranes

- Sponge and Foam

- Solid Elastomers

- Plastics and Film

- Silicone Membranes

- EMI/RFI Shielding Materials

- Pressure-Sensitive Adhesives

- Electrical Insulation

- Customer-Supplied Materials

- Nylon

- Cheesecloth

- Nonwoven

- Crinoline

Our die-cutting equipment includes a 35-ton traveling head and 25-ton clicker press. We offer hot knife and cold knife cutting, which are great semi-automatic solutions for cutting webbing, binding material, straps, hook-and-loop, and more, while preventing fraying of the ends. Our experts will consider the material, complexity, budget, and more to determine the best method for your project.

Die-Cut Gaskets

Hygienic Fabrics & Filters’ Sheboygan, Wisconsin, operation offers cost-competitive custom die cut gaskets. Our custom die cutting capabilities include manufacturing seals for any industrial, hobby, OEM, military, energy, medical or transportation firm large or small.

Once a suitable material has been found, we will work with your design to create a steel rule die. The steel rule die will be laser cut to meet your exact shape and specifications. Steel rule dies can produce thousands of parts, depending on the material. The more parts that are cut using the die, the lower your piece price because the cost of the die is amortized over more parts. Following is a partial list of materials we can cut using steel rule dies.

- Fabric

- Burlap

- Canvas

- Cotton

- Felt

- Flannel

- Gore-Tex®

- Muslin (fabric)

- Polyester (fabric)

- Velvet

- Wool

- Metal

- Aluminum

- Brass

- Copper

- Paper

- Cardboard

- Tissue

- Plastic

- Acetate Acrylic

- Ethylene

- Polyethylene

- Polypropylene

- Polyurethane

- PVC

- UHMW

- Rubber

- ABS

- Buna-N Rubber

- Butyl

- Cellulose

- ECH

- EPDM

- Foam

- Gum Rubber

- Hypalon®

- Latex

- Neoprene

- Nitrile (rubber)

- Perfluoroelastomer

- SBR

- Silicone Sheeting

- Sorbothane

- Sponge

- Misc

- Fiberglass

- Foam Core

- Graphite

- Lexan

- Magnet Materials

- Masonite

- Polycarbonate

- Shim Stock

- Teflon®

- Velcro

- Vinyl

- Wood

Clean-Room Services, ISO Class 6-Compliant

The Sheboygan, Wisconsin, location of Hygienic Fabrics & Filters maintains an ISO Class 6-compliant clean room to ensure high-quality products for food, medical, filtration, and electronic components. Clean rooms are well isolated and controlled to prevent contamination.

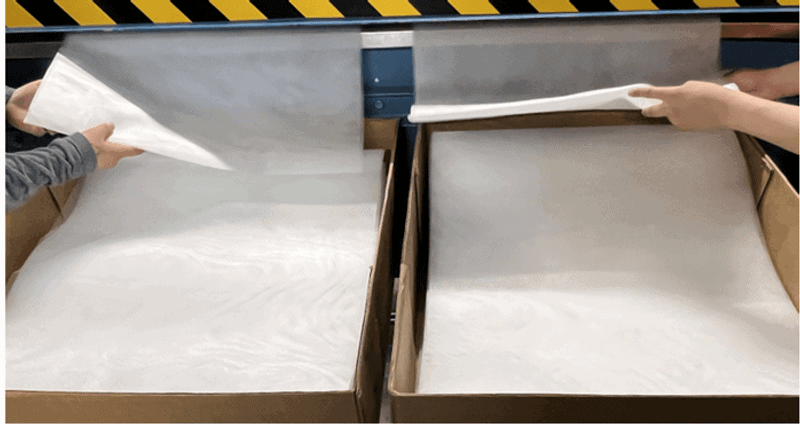

Hygienics Fabrics & Filters can do assembly, packaging, die cutting, custom slitting, subassembly, and heat sealing in the clean room.

Clean Room Die Cutting. Clean room die cutting combines the speed and precision of die cutting with reduced contamination, a priority for food, medical, filtration, and electronics applications.

Applications for Cleanroom Die Cutting:

- Medical and Electronic Device Components

- FDA Elastomers and Silicones

- Foams, gels, and adhesives

- Filtration and packaging

- Food contact materials

Contact us to talk with a member of our expert staff to learn how we can help you with our clean room services.

Finishing Services

Whether you require cutting, folding, sewing, or packaging, every step required for your project is offered inhouse at our Sheboygan, Wisconsin, facility. This allows us to easily handle high-volume orders while ensuring quick turnarounds and superior quality — even when working on complex, specialty, or brand-new products.

Assembly/Subassembly

Packaging

- Packing

- Heat Sealing

- Vacuum Pack

- Bulk Pack

- Kitting

- Labeling

- Warehousing

- Just-in-time delivery

Pair our clean room cutting, sewing, sheeting, and die cutting services with clean room packaging to maintain contaminant-free cleanliness from start to finish.

Contract Manufacturing

We invest in people, equipment, machinery, and space to handle each job. We focus on quality and productivity in the performance of each contract job.

Our Sheboygan, Wisconsin, facilities are ISO 9001:2015 Certified as a testament to our ability to meet high standards. Our continuous improvement and process review applies to all of our work to improve quality while reducing costs.

Hygienic Fabrics & filters has invested in converting and packaging equipment. Our facilities are clean and safe. Customer satisfaction is paramount in all we do.

Hygienic Fabrics & Filters is your go-to source for contract manufacturing in the Sheboygan, Wisconsin, area as well as the entire continent. Contact us when you need contract manufacturing services. We guarantee your complete satisfaction.

Fabric Welding

Need Additional Information?

For any additional information on any of our products or services, please send us an email or give us a call!

Contact HYFAB