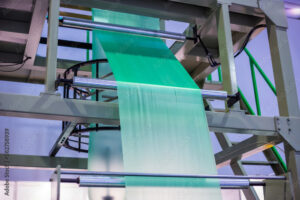

HFF specializes in custom steel rule die cutting of plastic films, netting, adhesive tapes, fabrics, and silicone rubber. From simple to intricate parts and large format to small prototype runs, we can die cut parts to tight tolerance specifications. We can produce gaskets, seals, shims, gap fillers, washers, discs, and squares, and we specialize in cut parts directly from customer supplied drawings.

HFF specializes in custom steel rule die cutting of plastic films, netting, adhesive tapes, fabrics, and silicone rubber. From simple to intricate parts and large format to small prototype runs, we can die cut parts to tight tolerance specifications. We can produce gaskets, seals, shims, gap fillers, washers, discs, and squares, and we specialize in cut parts directly from customer supplied drawings.

We can drill various hole sizes and make notches in your material, which is great for marking locations of grommets, snaps, or folds. Fabric die cutting allows for virtually any shape to be cut with consistency and accuracy. We can use your existing dies, or our team can create a custom die.

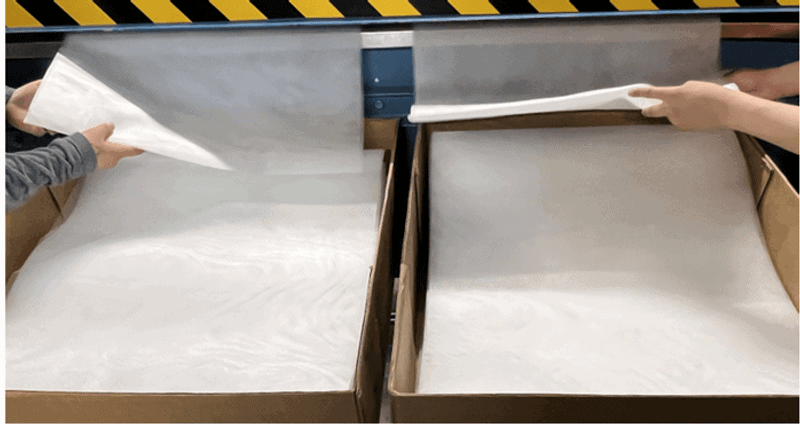

HFF offers rapid prototyping and short lead times as well as special packaging for medical products. Our state-of-the-art equipment, cutting-edge technology, and highly qualified and experienced staff distinguish us from the competition.

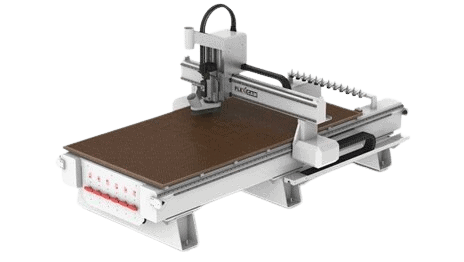

The steel rule die is the heart of die cutting. Formed metal blades are positioned in a wooden board to form a “cookie cutter,” which enables perfect duplication of your parts within .020″ every time. Complex shapes, stars, circles, and many different patterns are possible with a steel rule die. Using steel rule dies, we can die cut foam, sheet plastic, corrugated plastic, chipboard, fabric, rubber, felt, cork, thin metals, wood, acrylic, composites, fiberglass, magnets, sponge, custom die cuts or any other flat material normally found in the industry.

HFF can use customer-supplied steel rule dies or order a steel rule die for the job based on a dimension drawing. The tooling cost to create the die will be separately listed in your quote from HFF.

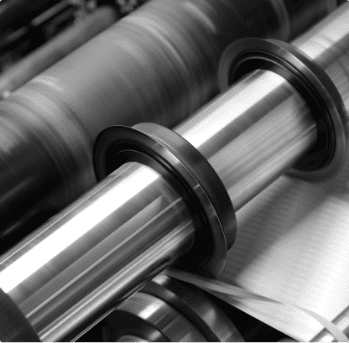

All of the products we cut require a very clean production environment and perfect packed appearance. We take care to follow all instructions for cutting and packaging regardless of job size. HFF provides precision die cutting services supporting tight tolerances, small and large part sizes, and various production volumes. Here, at our Made in the USA manufacturing facility in Sheboygan, Wisconsin, we provide precision die cutting services using high-quality tooling and state-of-the-art equipment. HFF can die cut materials such as:

- Membranes

- Sponge and Foam

- Solid Elastomers

- Plastics and Film

- Silicone Membranes

- EMI/RFI Shielding Materials

- Pressure-Sensitive Adhesives

- Electrical Insulation

- Customer-Supplied Materials

- Nylon

- Cheesecloth

- Nonwoven

- Crinoline

Our die-cutting equipment includes a 35-ton traveling head and 25-ton clicker press. We offer hot knife and cold knife cutting, which are great semi-automatic solutions for cutting webbing, binding material, straps, hook-and-loop, and more, while preventing fraying of the ends. Our experts will consider the material, complexity, budget, and more to determine the best method for your project.